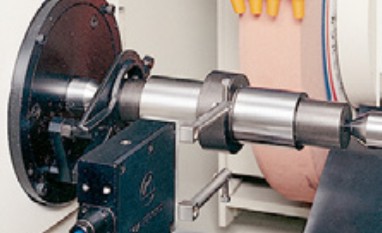

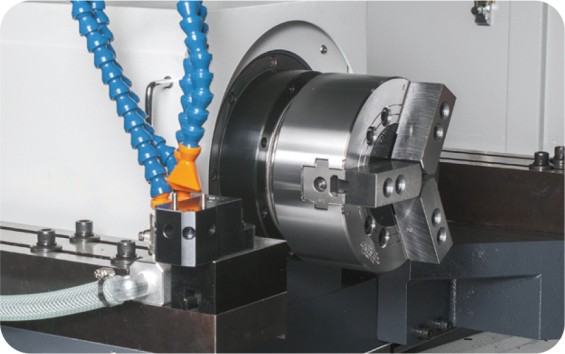

Regular cleaning and lubrication: clean the grinder regularly, remove dust, chips and other impurities, and keep the equipment clean. At the same time, the lubrication system is checked and supplemented to ensure the smooth operation of each component. Check and adjust: Check the accuracy and stability of the grinding machine regularly, including key parameters such as guide rail clearance and spindle accuracy. Adjust and repair the problems found in time to avoid the expansion of problems affecting the processing quality. Replacement of worn parts: Timely replacement of severely worn parts, such as bearings, belts, grinding wheels, etc., to ensure that the equipment is always in the best working condition.

Grinding machine solutions

Regular cleaning and lubrication: clean the grinder regularly, remove dust, chips and other impurities, and keep the equipment clean. At the same time, the lubrication system is checked and supplemented to ensure the smooth operation of each component.

Inspection and adjustment: Check the accuracy and stability of the grinding machine regularly, including key parameters such as guide rail clearance and spindle accuracy. Adjust and repair the problems found in time to avoid the expansion of problems affecting the processing quality.

Replacement of worn parts: Timely replacement of severely worn parts, such as bearings, belts, grinding wheels, etc., to ensure that the equipment is always in the best working condition.